Pros and Cons of Continuously Variable Transmissions

A Continuously Variable Transmission, better known as a CVT, is a relatively new type of automatic transmission that’s gaining traction among automakers and drivers. Here at Marshall’s Transmission Service in Collinsville, IL, our auto repair experts specialize in diagnosing and fixing CVT problems.

What is a Continuously Variable Transmission?

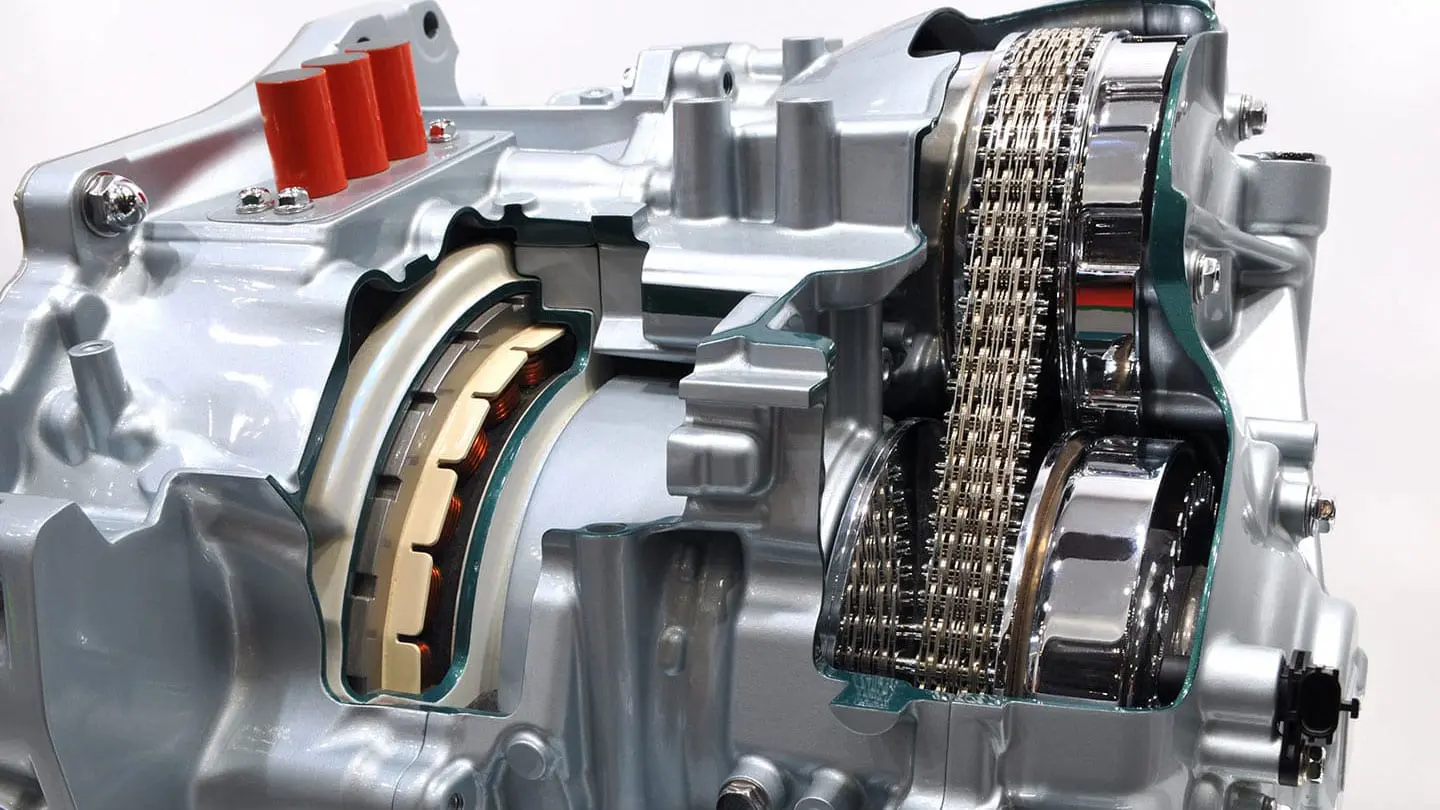

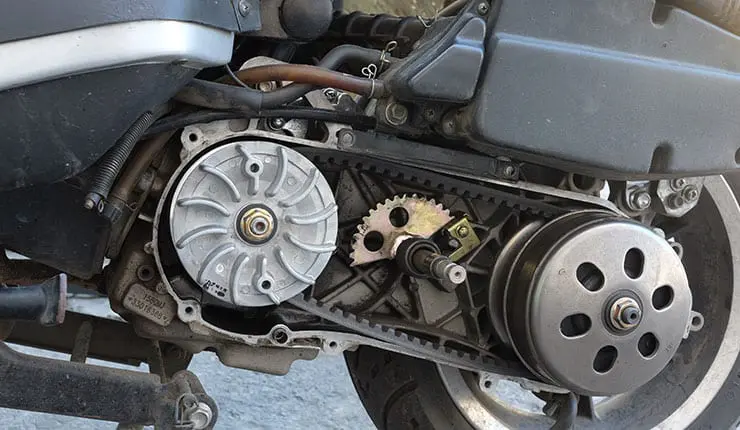

A CVT is an automatic, gear-less transmission that uses a set of variable-width pulleys linked with a flexible belt. First proposed by Leonardo da Vinci in 1490, on most CVTs, the pulley is mounted on the engine, and the other pulley is linked to the drive wheels.

When a driver accelerates in a CVT-equipped vehicle, power is transferred to the transmission via the pulley system. There are three types of CVTs: hydrostatic, pulley-based, and toroidal, with the most common pulley-based type.

CVT transmissions are standard on many Honda, Toyota, and Subaru cars and SUVs, while many domestic cars, trucks, and SUVs come equipped with a conventional geared automatic transmission.

How is a CVT Different From a Traditional Automatic Transmission?

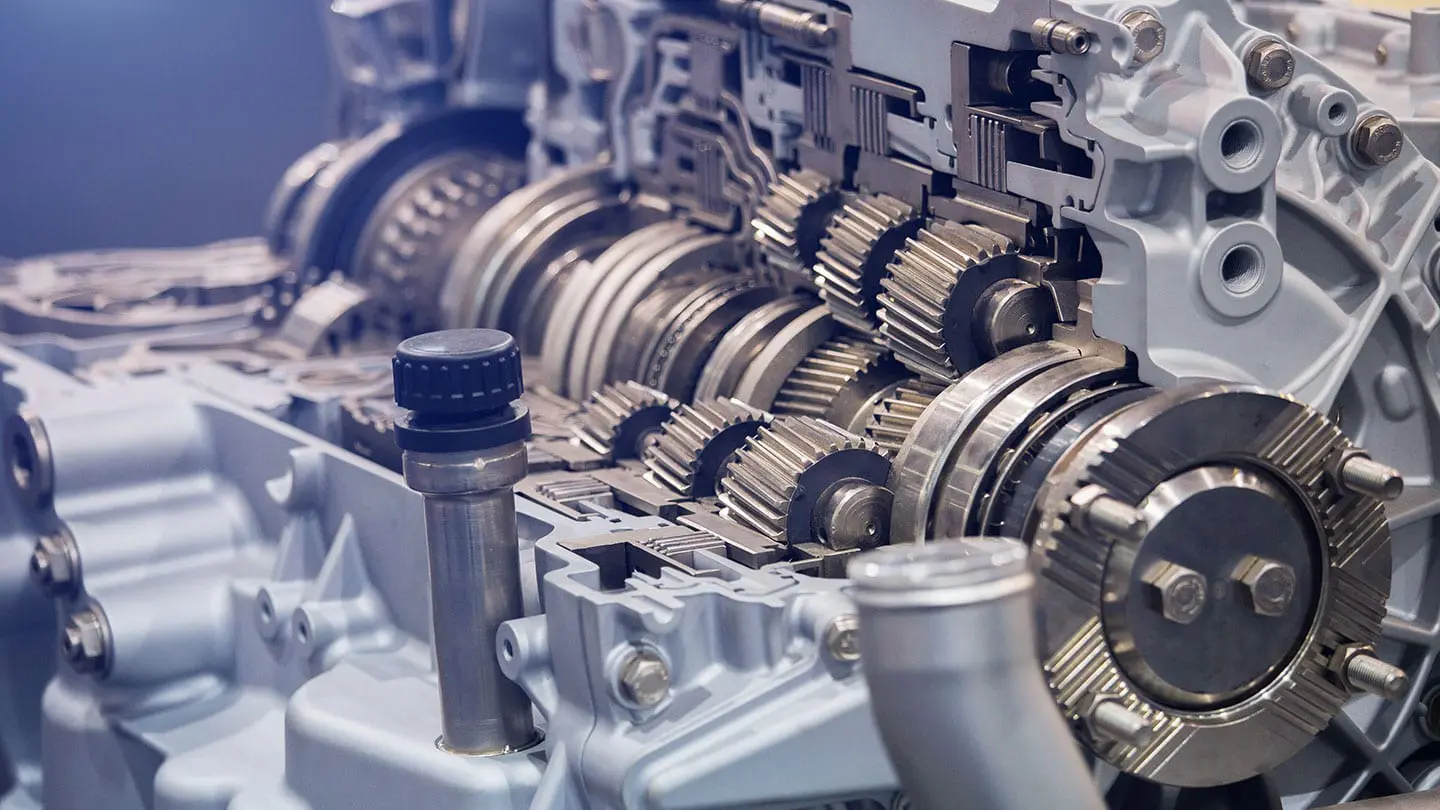

A traditional, gear-based automatic transmission has a gearbox with a variety of gear ratios. On most vehicles, there are six automatic gears; however, some high-end cars have up to nine gears. When the driver hits the gas, the transmission automatically selects the mechanical gear that produces the optimal torque to propel the drive wheels.

By comparison, a pulley-based CVT transmission delivers power to the drive wheels through a cone-shaped pulley system rather than gears, which means there aren’t any pre-set gears on a CVT-equipped vehicle. The pulley widths automatically adjust to deliver power to the wheels, and as one pulley gets wider, the other one narrows.

There’s no difference between a CVT and gear-based transmission in terms of driving the vehicle. What drivers do notice is that a CVT-equipped car doesn’t shift gears, and that can be somewhat unnerving for drivers and their passengers. To combat this odd driving sensation, some car makers have added computer-controlled ‘shift points’ to their CVTs to give drivers a more familiar on-road experience.

Another notable difference with CVT-equipped vehicles is that they deliver better fuel economy than comparable cars with conventional, gear-based automatic transmissions. This improved fuel economy is because CVTs constantly adjust to maximize engine performance, which also lets manufacturers use smaller, more efficient engines without compromising on performance.

CVT vs. Traditional Transmission - Which One is Better?

Both CVT and traditional, gear-based transmissions are widely used by automakers worldwide. Both types of transmissions have pros and cons, and it comes down to a matter of personal preference.

CVT transmissions are known for delivering a smooth ride that’s free from the usual gear changes. When paired with the right engine, CVTs can also make for quicker accelerations from a stop. The more responsive acceleration is also due to CVTs’ weighing less than geared transmissions, helping to reduce the overall weight and drag of a vehicle.

On the other hand, traditional geared automatic transmissions have been used in mass-produced cars since 1939 with the introduction of Oldsmobile’s ‘Hyrda-Matic’ shiftless transmission. By 1948, GM’s Hydramatic transmissions were also used in Pontiac cars, and by 1960, about 70% of all vehicles on the road in the U.S. had a geared automatic transmission.

It is important to note that the average cost of auto repair services on CVT transmissions is higher than with a geared automatic transmission. CVTs require a particular type of transmission fluid, and the parts to repair a CVT are often pricey.

What Are Common Continuously Variable Transmission Problems?

As with all machines, CVT transmissions need regular maintenance to help prevent costly auto repair bills.

Some of the most common CVT problems include:

- Slipping, jerking, or shuddering under acceleration

- Sudden loss of power while driving

- Loud, high-pitched noise when accelerating

- Leaking seals and gaskets

Spotting a fluid leak from a CVT can be especially challenging since many CVTs use pale-colored transmission fluid rather than the typical red color used on most conventional transmissions.

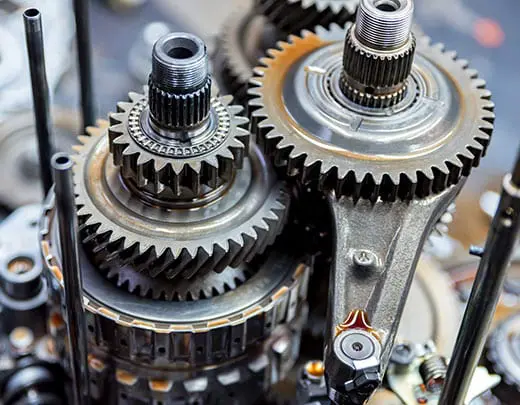

Because CVTs rely on a steel chain to transfer power from the engine, chain failure can be catastrophic. When a CVT chain breaks, it often shatters, propelling shrapnel throughout the transmission and adjacent parts.

How Can I Prevent Continuously Variable Transmission Problems?

Regular maintenance will go a long way towards preventing severe CVT problems such as slipping belts, chain failure, and fluid leaks. As with most lubricated machines, CVT transmissions require clean, fresh fluid to function correctly, and the straps and chains should be periodically checked for wear and tear.

Here at Marshall’s Transmission Service in Collinsville, IL, our team of auto repair experts has the skills and specialized equipment needed to take care of your CVT-equipped car or SUV. We can perform factory-recommended maintenance such as fluid changes, and we also rebuild, repair, and replace transmissions.